RSPO sits down with Fabio González, CEO of Palmas del Cesar, who shares about their circular economy projects delivering socioeconomic sustainability in palm oil production.

In central Colombia, one company is living up to its pioneering spirit by becoming the first in the country to employ circular economy innovations in palm oil production. Palmas del César, which was the driving force guiding the first group of Colombian smallholders towards RSPO Certification last year, is now stepping up its sustainability efforts by embracing circular principles through a 30,000 square metre bio compost plant that turns industrial biomass into fertiliser as well as captures and processes methane gas emissions into biogas for generating electricity.

“We’re a company philosophically connected to sustainability,” shares Fabio González, CEO of Palmas del Cesar. In this exclusive interview with Fabio, RSPO explores their fruitful pursuit of circular innovations through high level engineering and the keys to Colombia’s sustainability leadership.

Palmas del Cesar was one of the pioneers in palm cultivation in Colombia. What makes your company stand out in the industry?

We’re a company with very high standards. We’ve been a reference for good practices in all areas of palm cultivation in Colombia. We’ve been recognised for our labour relations management, such as the “Great Place to Work” certification, which is also important for our people. We also have the RSPO Certification, the Zero Deforestation agreement with Fedepalma, and the ISCC certification standard for our carbon footprint.

What is the current production capacity of Palmas del Cesar?

Our crops cover about 4,000 hectares, and we have another 10,000 hectares with our allied palm growers , forming a nucleus of approximately 14,000 hectares. Our processing plants have a capacity of 75 tonnes. We employ about 750 workers, including 110 women, many of whom are heads of their households.

Indirectly, we generate around 600 jobs, and our allied palm growers generate another 1,500 jobs. Thus, we form a palm nucleus in southern Cesar, and we are a driver of development. Our foundation supports social policies for seven communities, benefitting around 8,000 people through various programmes such as Productive Women, educational initiatives for the elderly, and sports programmes.

What was your first encounter with Circular Economy, and how did it align with the company’s own sustainability goals?

Because sustainability is something that has become almost a mantra for us, sustainability must be made real with concrete actions. We didn’t want to just give a speech about sustainability and certifications without addressing real challenges in palm cultivation.

The biggest challenge in palm cultivation concerning environmental balance is managing the thousands of tonnes of biomass produced. About six years ago, we attended a PIPOC Congress in Malaysia, where the slogan was: “Biomass is gold.” There are many opportunities to improve environmental conditions and also make sustainability generate income for the entrepreneur.

Undertaking these projects demands many resources, but they are also very rewarding, as they return those resources. Circular economy involves taking biomass, adding value to it, and returning it to the cultivation in some cases, or converting it into kilowatts of energy to produce electricity. It fulfils both environmental and social goals by reducing the carbon footprint, addressing climate-related issues, and providing income opportunities.

Could you tell us about your circular economy initiatives?

We created two project fronts: one is a gigantic bio compost plant with enormous greenhouses, covering 30,000 square metres, where we deposit the solid biomass from the industrial plant, which includes bunches and smaller biomass like husks and ashes. Through a standardised, controlled process under very clean conditions, we transform this biomass into compost in 40 days. This compost enhances soil and provides nutrition to the palm, exemplifying a perfect circular economy.

Additionally, the industrial plant produces a lot of effluents, which is a huge challenge as it releases approximately 60,000 tonnes annually of palm oil mill effluent (POME). Normally, this is managed with systems to treat the POME, but it emits methane gas, which is a greenhouse gas, into the atmosphere. We capture it using covers and process it, or, in the next step, by generating electricity with engines powered by this biogas.

With compost, we produce 20,000 tonnes annually for our crops, and with biogas, we will generate eight million kilowatts to sell to renewable energy networks.

These are two leading projects that we hope will encourage other plants in the region to follow as circular economy examples. In fact, several are already working on similar projects, contributing significantly to agriculture and the environment. The neighbouring plants are also RSPO Certified and very committed to sustainability. We are proud pioneers in the region, being the first to produce kilowatts and having implemented compost production this year.

Where is the biomass taken from?

The biomass is produced in the industrial plant during processing. The other biomass includes leaves from the cultivation, which they use in agricultural practices developed by Cenipalma. The foliage is left on the soil, which is also important biomass. We can also sell the compost we produce to improve crops.

What have been the biggest challenges in facilitating your circular economy initiatives?

It is mainly on high-level engineering – these projects demand expertise and must be done very well technically due to stringent engineering specifications. There are various ways to make compost, but beyond that, the site must be designed to prevent residues from contaminating water sources.

We made significant investments in engineering to design the subsoil of the compost plant to avoid such contamination. Similarly, in the biogas plant, where we treat POME and capture methane, the design involves complex systems and high pressure. The challenge was acquiring good engineering, studying the projects thoroughly, and getting expert advice.

As a Colombian company recognised for its pioneering innovations in sustainability, what would you say are the reasons driving Colombia as a sustainability leader itself?

Fedepalma has worked extensively to promote sustainability among palm growers, emphasising Colombia’s development model, which includes providing support to other players within the palm oil ecosystem to better incorporate sustainability into their daily work. We refer to these players as “palm nuclei.” There are at least 50 palm nuclei currently supported byFedepalma and the research centre, Cenipalma.

The Colombian palm model has facilitated rapid spread of sustainability concepts, leading to significant growth in this area. Fedepalma’s National Zero Deforestation Agreement has also been a guiding force for us.

How would you want the sector to grow?

I see the sustainable palm sector increasingly conquering markets and demonstrating its potential for environmental balance and carbon neutrality, even carbon negativity. It’s a crop with great potential in this regard.

In the coming years, I see palm oil solidifying its position in new markets like the United States and becoming strong in Europe, despite the challenges from the EU. Palm cultivation has the capacity to socially transform many people because it’s a perennial crop that stays for decades. Companies arrive in regions to stay and drive development. This adds not only environmental but also social value, making palm oil a good product in the global market.

Keep reading

Book Your Slot for the Additional prisma Clinic Session at RT2025

Advancing Jurisdictional Certification in Sabah: Strengthening Collaboration Between RSPO, UNDP, and Jurisdictional Approach System for Palm Oil (JASPO)

Call for Expression of Interest: Independent Investigation of a Complaint

Leading Labels: RSPO Among Top Sustainability Labels in Dutch Market

The 21st International Oil Palm Conference Successfully Took Place in Cartagena, Colombia

Top Performers of the 2025 Shared Responsibility Scorecard

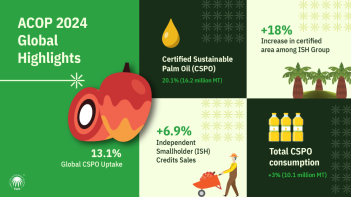

ACOP 2024: RSPO Market Trends Resilient Despite Global Challenges

RSPO: Actions for the Certification of Sustainable Palm Oil Production