Exploring the immense potential of regenerating oil palm waste and by-products through circular solutions, with a closer look at RSPO Members adopting circular economy practices.

In recent years, the circular economy model has become a prominent feature as a greener approach to transforming the palm oil industry.

Circular economy focuses on waste minimisation, symbiosis and zero waste concept at the plantations and mills. This model also tackles climate change and other global challenges, including biodiversity loss and pollution. Adopting a circular economy will significantly lower production cost by reutilising the waste or by-products of palm oil, utilising them as solutions to address the issues of waste pre-treatment– examples of this include palm oil mill effluent (POME) needing to be pretreated before its release to water sewerage; and empty fruit bunches (EFB), which when left to rot at the plantation or mills, become dangerous as they release greenhouse gas (GHG) emissions to the atmosphere which are 20 times higher than carbon dioxide. By regenerating these waste products through circular solutions, not only do they benefit the environment and help mitigate climate change, they also provide cost saving measures as well as avenues for income generation for growers and smallholders.

Shift to renewable energies

As the world transitions into a circular economy, the abundant oil palm biomass available in palm oil producing countries and regions such as Indonesia, Malaysia, Latin America, Thailand, and others, are still underutilised, especially for the high value chemicals and materials that take centre stage. Biomass will be the future replacement of fossil-based applications such as petroleum, petrochemicals, coal, and others. Most of the world’s industry players (oil and gas, energy and utilities, aviation, shipping and logistics, and heavy industries such as steel and cement, and the manufacturing sector) are shifting towards the use of renewable energy and renewables in their operations as part of their energy transition, decarbonisation, and net zero direction. As such, the valorisation of oil palm biomass waste and residues into high value products and applications (termed “waste-to-wealth”) will be the key to a more sustainable future for all industries.

Biomass potential

The potential applications from biomass are immense. They include (but are not limited to) advanced biofuels production, including sustainable aviation fuels (SAF); high value biochemicals used in our daily lives; bioenergy regeneration, bioplastics or bioresin to replace fossil-based plastics; and medium density fibreboards (MDF) for the furniture, paper and food packaging, animal feed and biochar.

Circular economy and utilisation of oil palm biomass waste stream can become a new source of income and revenue, not only for processors and traders, mills, and refiners, but also for growers and smallholders who could eventually benefit from the supply of the oil palm biomass. One way is by supplying oil palm trunks (OPT) and oil palm fronds (OPF) to biomass traders, aggregators, and future biorefinery plant owners. Furthermore, the deployment of biorefineries in rural areas stimulate regional and rural development as well as increase the livelihood of smallholders and communities.

RSPO Members adopting Circular Economy

A number of RSPO Members, such as Sime Darby Plantation (SDP), Felda Global Ventures (FGV) Holdings, and Kuala Lumpur Kepong (KLK) to name a few, have already embarked into various circular biomass waste and residue projects to transition towards circular and greener business – from either sourcing sustainable biomass feedstocks and/or adopting circular economy practices as part of their business operations. These include installing biogas or methane capture facilities at their palm oil mills for renewable energy generation to power their own energy consumption. Such circular initiatives not only improve waste management but pursue renewable energy solutions in order to meet corporate emission reduction targets.

FGV owns 28 biogas plants and is among the first to develop a palm-based, bio-compressed natural gas (Bio-CNG) plant from POME. Moreover, KLK currently has nine operational biogas power plants and SDP targets to have 40 biogas plants as part of its Net Zero goals by 2050.

Another example of an RSPO Member currently involved in circular business is NextGreen Global. With operations at the Green Technology Park, an eco-innovative, self-sustaining industrial park located in Pahang, Malaysia, the company is behind the world’s first technological breakthrough in pulp and paper production with renewable energy and waste recovery technology utilising EFB biomass to be converted into paper, food packaging products, animal feed, fertiliser, lignin, and pharmaceutical products. This is an example of a zero waste facility, as waste and by-products from every production process are fully utilised through conversion into functional green products and renewable energy.

IOI Palm Wood Sdn. Bhd adopts circular economy practices such as converting oil palm trunks biomass into block-boards and other engineered panels for furniture to address the shortage of rubber tree and timber residues in the region. The Petronas circular project converts EFB to Bio-MEG to replace fossil-based resources, while FGV produces sustainable insect protein from the black soldier fly that consumes oil palm decanter cake and palm kernel cake (PKC) biomass to animal feed.

Growing demand for sustainable biomass certification

It is important to acknowledge that the biomass industry players are demanding for biomass waste and residue to be certified in order for the biomass to be exported globally and obtain international recognition in the future. Raising awareness of climate change has led to changes in countries’ policies towards sustainability.

Evolving regulatory landscapes are giving rise to demand for sustainable certification for biomass. For example, the Japanese government, under its Ministry of Trade & Industry (METI), will begin enforcing the new regulation in the utilities and power sector, which are currently importing and using palm kernel shells (PKS) and EFB biomass as feedstock for renewable energy to acquire third-party sustainability certificates from April 2024.

Strengthening the circle

In line with these developments, RSPO will continue to support members and partners embarking in circular development projects and those sourcing sustainable biomass feedstocks for their future facilities and refineries.

In conclusion, a circular economy is a possible avenue to address the waste problem with its circular nature. The focus is now to be more optimistic and move towards producing higher-value biobased products from oil palm biomass waste. RSPO encourages its members to leverage this opportunity and welcomes the right partners with suitable technologies to ensure resource-efficient valorisation of biomass to establish more sustainable oil palm biomass projects.

This once again highlights the natural efficiencies of oil palm, and why investing in sustainable palm oil is the way forward.

Editor’s note: The Circle Series will be a special feature exploring the potential transformative impacts of the circular economy on the sustainable palm oil sector.

About the author: Thareq Ariffin is RSPO Market Transformation (Malaysia & Singapore). To get in touch, write to him at [email protected].

Keep reading

Book Your Slot for the Additional prisma Clinic Session at RT2025

Advancing Jurisdictional Certification in Sabah: Strengthening Collaboration Between RSPO, UNDP, and Jurisdictional Approach System for Palm Oil (JASPO)

Call for Expression of Interest: Independent Investigation of a Complaint

Leading Labels: RSPO Among Top Sustainability Labels in Dutch Market

The 21st International Oil Palm Conference Successfully Took Place in Cartagena, Colombia

Top Performers of the 2025 Shared Responsibility Scorecard

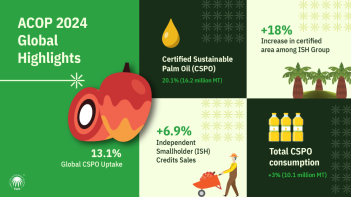

ACOP 2024: RSPO Market Trends Resilient Despite Global Challenges

RSPO: Actions for the Certification of Sustainable Palm Oil Production